Alloy wheels markings, detailed explanation

Alloy wheels markings, detailed explanation

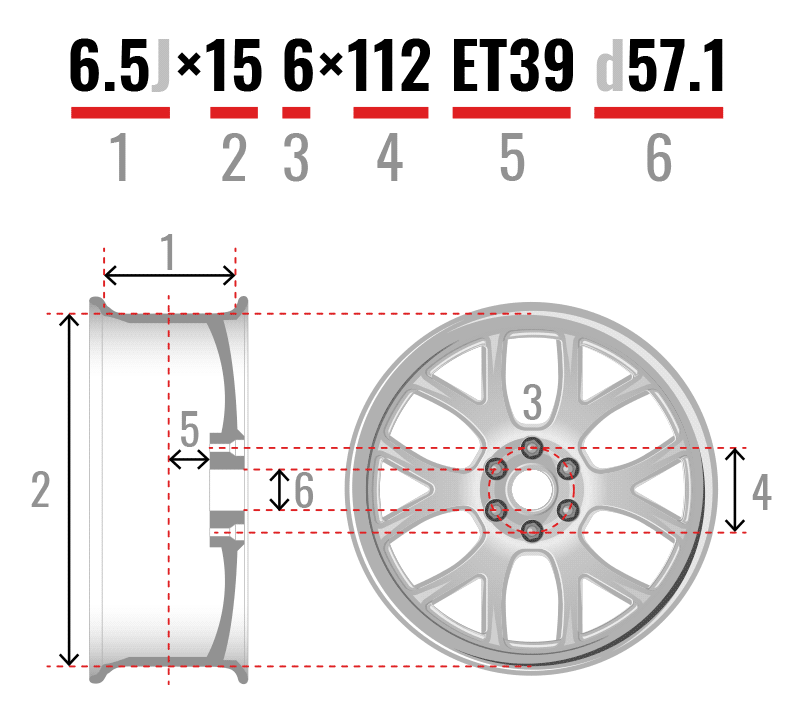

1. The width of the disk in inches (sometimes this value is indicated in the marking as a fraction 6½). The width is measured not along the outer sides of the rim, from edge to edge, but along the so-called “disc shelf”, on which the sidewalls of the tire rest. The width of the tire and rim must strictly correspond to each other so that the tires, after installation on the rims, have the optimal shape specified by the manufacturer. After the disk width, the type of bead profile or the shape of the wheel flange can optionally be indicated. Identified by the letters J, JJ, K, JK, B, P and D. Indicates the shape of the wheel where the tire bead sits on the wheel.

2. Rim diameter in inches Note that rim diameter is not the outer diameter of the rim from edge to edge, and like width, it is the diameter of the rim “flange” on which the tire bead rests.

3. Number of mounting holes for bolts or nuts.

4. PCD (Pitch Circle Diameter): The diameter of the circle on which the mounting bolt holes are located. In the case of an even number of bolts, this parameter is equal to the distance between the centers of opposite holes. However, in the case of an odd number of bolts, the PCD will be difficult to measure using available tools. Sometimes, for simplicity, both of these parameters are often called PCD at once (the number of bolts and the diameter of the circle), and when indicating the PCD of the disk they write 5/112 or 5x112.

The disc bolt pattern must be observed: despite the fact that some discs - for example, 4x98 and 4x100 - seem to be interchangeable, this is not the case. A seemingly insignificant 2 millimeter difference in the diameter of the circle on which the mounting holes lie will greatly affect the installation: only one of the four fastenings will be correctly tightened, and the rest will be offset from the center, causing the wheel to run out. The problem can be partly solved by using bolts with a “floating cone”, but in general the use of discs with unsuitable bolt patterns should be avoided. Bolts with the so-called “floating cone” make it possible to partially compensate for the slight discrepancy between the PCD disk and the required parameters - the working conical part of such bolts is made in the form of a separate ring, put on the bolt, and moves relative to the longitudinal axis of the bolt when tightened.

5. Disk offset ET (from German "Einpresstiefe" - indentation, compensation). This parameter may also be marked OFFSET and DEPORT. Disc offset is the distance between the mating plane of the wheel rim (the plane of which the disc is pressed against the hub) and the middle of the rim width. In simple words, this parameter shows how much the disk relative to the hub will be shifted outward or inward of the car body.

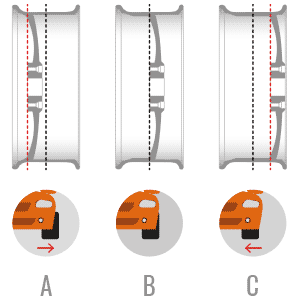

Rim offset (ET) is measured in millimeters. There are discs with negative offset (A) and positive (C). If the center of the disk coincides with the plane of attachment of the disk to the hub, then the disk offset will be zero (B). In our case under consideration, ET is positive and equal to 39 mm.

Rim offset (ET) is measured in millimeters. There are discs with negative offset (A) and positive (C). If the center of the disk coincides with the plane of attachment of the disk to the hub, then the disk offset will be zero (B). In our case under consideration, ET is positive and equal to 39 mm.

Offset is one of the most important indicators of a wheel that affects the stability and controllability of a car. With a reduced offset, on “widely” spaced wheels, the force on the steering wheel, as well as the load on the hub bearings, increases significantly. A wheel with an increased offset is shifted deeper into the wheel arch and can, when turning or large suspension strokes, touch vehicle elements, which will lead to damage. It is not recommended to deviate from the standard offset value by more than 3-5 mm in one direction or another.

6. The diameter of the center hole (DIA or D) that is used to center the wheel on the machine hub. If a wheel is purchased with a smaller D value, it will not be able to “sit” on the hub, if with a larger one, it will require a special centering ring. The diameter of the central hole is measured in millimeters.

When choosing wheels in the pit-stop online store, you can filter the wheels both by the make of the car they fit and by any of the above parameters.

Pros and cons of alloy wheels

“Casting” is characterized by high strength and rigidity with less weight. It is no coincidence that aluminum alloys are actively used in the aerospace industry. It is quite difficult to break a cast disc as a result of an impact, but they are still unable to handle too strong impacts. And the consequences can be catastrophic - the wheel will simply break and cannot be repaired.

Aluminum is capricious in winter: ice and reagents provoke its corrosion, and in cold weather the alloy becomes more fragile and can burst with a strong impact.

If an alloy disk on a car bursts, there is no point in restoring it. Even a chip or dent may require disc replacement. And finding a disc with the same design years after purchase can be problematic. We have to change the entire set.

The weight of a cast wheel depends on its shape and design. But in any case, “casting” is noticeably easier than “stamping” of the same dimensions. And the smaller the mass of the disc, the lower the load on the chassis - impacts on it in holes and potholes are less intense. On uneven roads, a car with alloy wheels moves more comfortably.

However, the constant use of “casting” off-road is not justified and can be fatal for the wheel - the risks of damage to the disk and tires are too great. And even if the wheel takes a hit, it will transfer it more harshly to the suspension parts than a stamped one.

But on good roads such wheels are a definite plus. A disc of less mass is easier to spin and guide, so a car on a “cast” is more dynamic and stable. And when the car requires less effort to accelerate, fuel consumption also decreases.

Thanks to their sleeker design, alloy wheels provide better cooling for the braking system, which increases its effectiveness in extreme situations. But at the same time, less protection of calipers and hoses from foreign objects makes them more vulnerable on the same off-road conditions.

A cast disc under normal conditions has excellent corrosion resistance if the protective layer of paint and varnish on its surface has not been damaged. Perhaps only incorrect storage conditions and electrochemical corrosion can harm it, when the wheel is constantly heated (during intense braking) in contact with salt-based deicing agents. In general, the advantages of alloy wheels still outweigh their few disadvantages.

Care of alloy wheels

Cast wheels require special care because every scratch on them becomes noticeable, because a damaged layer of paint or varnish reveals pure aluminum, which quickly corrodes. The result is unsightly black spots on the surface of the rims.

Car rims generally tend to be the dirtiest part of the car. They are constantly exposed to external operational factors that negatively affect the varnish coating. First of all, these are: brake dust, road salt, stones, sand, adhesive resin and others. Damage to the protective coating on discs also occurs when they are washed in automatic car washes. Therefore, to minimize damage, special care is required for their condition.

Before installing alloy wheels on a car, it is worth covering them with a wax preparation applied to painted surfaces. This protects against dirt and makes future cleaning easier. New discs, especially at the beginning of use, are very susceptible to dirt, which, if neglected, accumulates and “bites” into the paint, creating a layer that is difficult to remove. Waxing should be repeated periodically, for example once a quarter.

The best way to care for alloy wheels without the risk of damaging their finish is to wash them frequently with soap and water or use a pressure washer. Cleaning heavily soiled wheels with strong acid-based chemicals is not the best solution. It is also not recommended to use chemicals to clean chrome wheels.

Beware of automatic car washes - some use acidic cleaners (before or during the wash) to remove dirt and caked-on residue, others may find harsh wheel and tire brushes - both of which cause damage to the wheel finish.

Alloy wheels heat up quickly and quite strongly. Therefore, they must be cooled before washing, since washing hot discs destroys the varnish coating. In addition, water dries much faster at high temperatures, leaving concentrated solutions of chemicals on the discs that cause previous damage to increase.

It is also not recommended to use low-profile alloy wheels in winter. Firstly, they are easily scratched by ice and frozen snow, and secondly, they have a very thin protective layer (only clear varnish) and are therefore more susceptible to the adverse conditions that prevail in winter.

All wheels coming to us for storage are automatically washed (DRESTER W550). In this case, only warm water, special plastic granules and compressed air are used. No chemicals, water circulates in a closed cycle, which guarantees gentle washing of your discs and an environmentally friendly process.

You can also order a manual disc wash at any time convenient for you. When washing by hand, we use a special wheel cleaner, Liqui Moly Felgen-Reiniger Spezial, which intensively and gently cleans aluminum and steel wheels. Easily removes abrasive brake dust and other dirt. Biodegradable and acid free. The whole process takes no more than 10-15 minutes.